Commercial internet sites rarely give you a perfect dirt account, a reasonable timetable, and also endless gain access to. Often you are threading structure elements around utilities, functioning below active pieces, as well as dealing with fill that looks like a geologic mixed greens. In those situations, integrating helical piles along with quality shafts uses a reliable, inspectable means to carry gravity and also side lots without the noise as well as clutter of steered stacks or the treatment times of cast-in-place deeper structures. Performed attentively, this pairing can easily reduce schedules, tighten up tolerances, as well as supply well-maintained lots pathways that stand up to settlement, freeze, and seismic demand.

Where Helical Piles and Grade Beams Fit

A helical pile is a steel shaft along with one or more coil plates that evolve right into the ground under twist. In commercial helical pile installation, we install them with gas electric motors that check out torque in real time, providing a price quote of capability connected to ground protection. Level shafts are actually strengthened cement participants that collect column or even wall structure lots and circulate all of them to separate help like heaps or even piers, while spanning unsatisfactory dirts between all of them. All together, they imitate a shallow beam remaining on centered points, a useful crossbreed for mixed dirts as well as constrained sites.

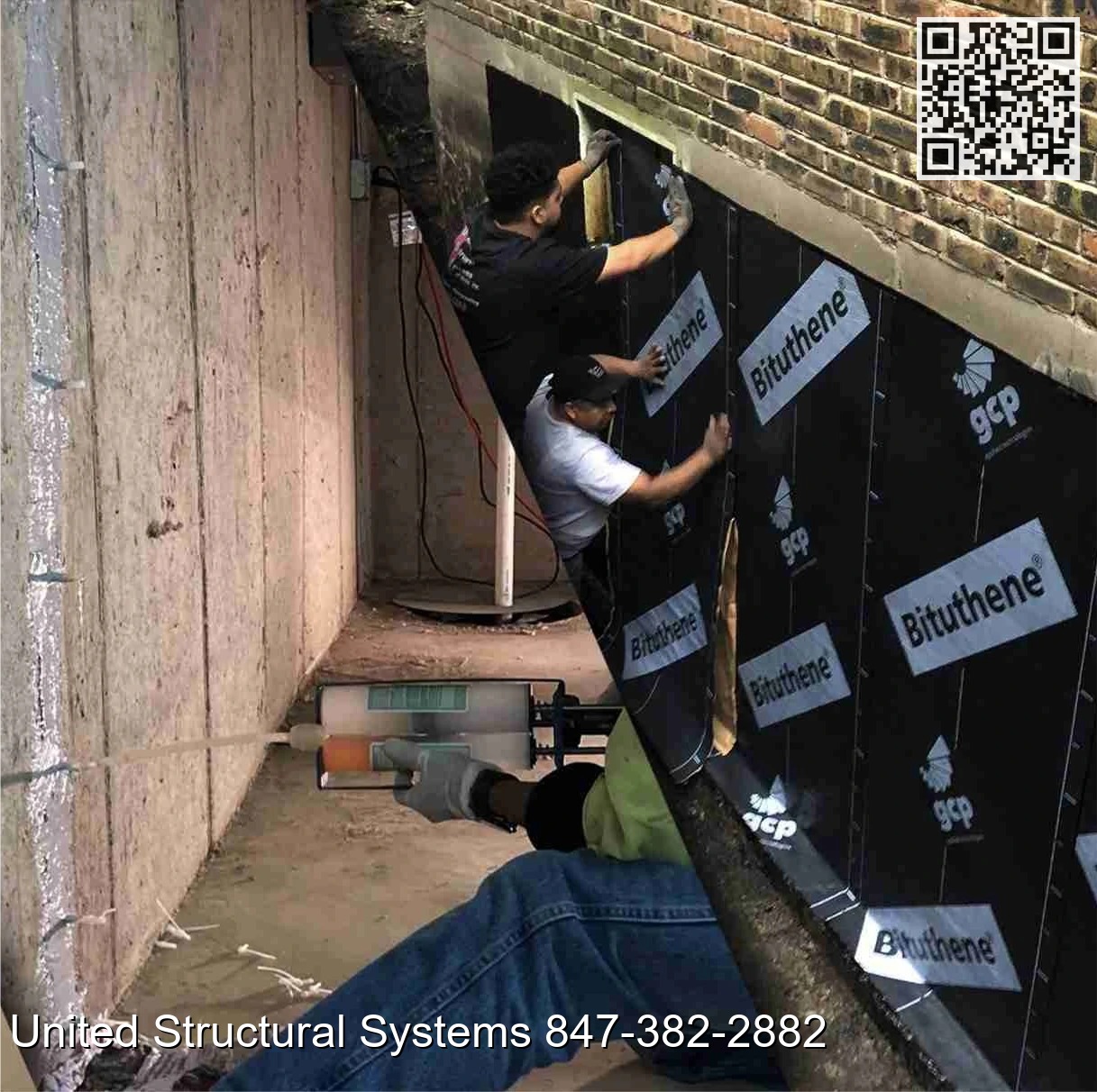

Integrating these units is actually certainly not a novelty. Our experts utilize helical piles to bypass compressible strata as well as chair in to dense sand or stiff clay-based, then tie all of them right into quality beams that grab brickwork wall structures, steel frames, or tools pads. Due to the fact that helical piles mount along with restricted vibration, they fit work adjacent to vulnerable locations like medical centers, data facilities, and also labs. When get access to is tighter than a full-size rig can manage, lead areas and extensions may match via door openings as well as take a trip down staircase centers. That flexibility serves in commercial foundation repair, structural foundation repair, and commercial foundation stabilization, where work takes place under existing structures.

Choosing Helical Piles As opposed to Alternatives

The option is actually hardly binary. On ventures along with high axial weights, resistance piles or even micropiles may compete on capability. On jobs along with abrasive soils or cobbles, micropile installation along with canvassed exploration can easily prove extra foreseeable. For lateral or uplift demands, helical tieback anchors may enhance upright piles at grade beams and also preserving elements.

I take a look at six aspects:

- Subsurface variability as well as obstructions: Helical piles struggle in gravels with large cobbles. If the dull logs reveal 2 to 6 in cobbles throughout, commercial micro pile installation along with cased boring may go smoother. Noise and also vibration restrictions: Helical anchors shine inside hospitals or near vibration-sensitive production. Centric resistance stacks generate additional disturbance. Access as well as space: Helical gears can easily collaborate with 8 to 10 feets of clearance. For cellars with a lot less, fractional micropiles might be the much better call. Load mix: Uplift or even web strain prefers helical piles as well as helical tieback anchors considering that the coil layers cultivate strain capacity immediately upon installation. Schedule and weather condition: No treatment opportunity means bunches may be transmitted to helical piles as soon as the level shaft cement scopes durability. If wintertime pours are sluggish, heaps can be proofed ahead of time to sustain momentum. Inspectability: Torque logs, tons exams, as well as verifiable rejection embedment offer documentation for the manager as well as building official.

There is a place for commercial resistance pile installation where soils are actually soft however impediment totally free as well as where a driven heap's set may be checked. Micropiles have a crystal clear lane when stone outlets are actually needed or when rocks and also particles will disperse helical flights. The method is to line up methods and techniques along with the subsurface and the building's needs, not the specialist's beloved tool.

Anatomy of the Bunch Path

Grade shafts accumulate column and also wall surface lots into discrete bearing factors. Each helical pile allows axial compression and often some pressure, depending upon the describing. Support in the grade beam takes care of shear and also transfers the bunches to the heap heads by means of hats or soldered links. On longer periods, the level beam likewise behaves as a flexural member, with lower steel for positive moment as well as best steel over supports for adverse moment. The stack team spacing is specified through dirt auto mechanics as well as building requirements, but the support must be ongoing around the shaft to maintain the tons pathway clear.

It pays off to look at the quality beam's hardness relative to the stacks. An incredibly tight shaft with adaptable piles simulates a continual girder on springs. If the spring seasons (piles) are actually certainly not equivalent in capacity or even stiffness, load sharing ends up being unequal. We improve for that along with constant twist criteria, preloading or even evidence exams, and in some cases, added piles under high minute areas. When a shaft crosses a power, the shaft depth may lessen, which alters tightness. The designer should expect that and change the pile design or reinforcement so the tons carries out certainly not concentrate at an unstable point.

Design Balance That Stops Field Pain

Coordinating geotechnical and architectural input early will spare you rework later. I talk to the geotechnical developer for permitted torque-to-capacity connections for the helical body we intend to utilize, not a general assortment. If they give torque-to-capacity factors for squeezing and strain, that lessens the RFI cycle throughout setup. The structural developer can easily after that size heaps and also level shafts with those connections and also established approval standards in the drawings.

Plan for real building tolerances: pile area within 2 inches, plumb within 2 per-cent, and cutoff altitude within half an in prevail intendeds. Quality beam crates often have congested rebar near heap hats. If the plannings call for moved studs on the pile caps, ensure the rebar clearances accommodate welding and also inspection. For a constant shaft, I prefer embedding pile heads right into the shaft with a steel plate as well as hairpins developed into the crate, which prevents awkward industry assembly inside forms.

On uplift or sidewise walls, combine vertical heaps with helical tieback anchor setup. Tiebacks installed at a 15 to 25 degree slant can easily limit wall action while the quality shaft takes gravitational force and distributes longitudinal bunches. In expansive clay-baseds, two-way pins and sleeves at pillars avoid locked-in tensions, and the helical piles bypass the swelling zone.

Construction Pattern That Works Under Genuine Constraints

Sequencing concerns as much as style. One trustworthy pattern for a retrofit under an energetic structure goes like this:

- Sawcut and also get rid of piece bits over future grade shaft pipes in 6 to 8 foot long doors, maintaining demolition regulated to restrict resonance. Shield surrounding places with dirt command and also unfavorable sky if the property is actually occupied.

With get access to in position, set out pile places making use of command collections pulled from repaired property sections. Assume a handful of contravene avenues or even unfamiliar footings. A portable ground-penetrating radar elapsed may minimize unpleasant surprises, but merely exploratory holes confirm the path.

Install helical piles along with an adjusted travel scalp as well as data logger. We record torque every foot, note modifications in dirt resistance, as well as validate that embedment reaches the aim at coil depth, typically a number of diameters listed below the most affordable coil. If torque peters and our experts overlook the minimum required, add an extension as well as carry on settling to the bearing stratum pinpointed in the geotechnical file. If twist spikes as a result of impediment, wiggle out and offset by 6 to 12 inches, at that point resume. On a regular retrofit grade shaft, stack spacing might rush 6 to 10 feet on facility, but space is actually a functionality of lots and also shaft stiffness.

Cut piles to elevation and connect hats. For square shaft or even sphere water pipes piles, limits might be actually bailed out or soldered. Where welding is specified, conform layers straight as well as protect bordering concrete advantages with helical pile foundations fire blankets. If hats are going to be projected right into the beam, put upright hairpins or headed pubs per the detail.

Set and link the level beam of light support. Enable good enough base cover to clear sporadic subgrade. Where existing footings or utilities reduce beam of light intensity, step the bars to maintain growth lengths and also continuity. If you expect differential motion between new and aged concrete, incorporate dowel pins along with epoxy yet limit beneficial nail down higher action soils.

Form the level shafts snugly around pile scalps. I prefer turn ports or adjustable banks in lengthy spans to restrict formwork curvature as well as always keep top-of-beam elevations correct. Verify anchor bolt design templates for any kind of foundation plates that remain on the grade beam of light. Small misalignments at this phase may develop into uncomfortable column plumb concerns later.

Pour along with a workable mix that are going to stream around hats as well as reinforcement without partition. In low-headroom rooms, prepare for pump lines transmitted through primary openings or short-term sleeves. Shake meticulously around heap scalps so you do not move the caps.

Once cement scopes defined toughness, transfer tons steadily. If the job is a commercial foundation repair under an existing wall surface, port and shim in small increments, watch split assesses, and paper movement. When our team elevate as well strongly, existing finishes demonstration prior to the framework does.

Detailing Pile-to-Beam Connections

The connection is where many installments stumble. A helical pile is merely like the method it interacts the quality shaft. For compression-only conditions, a flat platter hat with bonded shear tabs as well as pins that establish above home plate operates well. For pressure, the hat needs a favorable mechanical hookup like a through-bolt, moved studs, or a welded pipeline socket that interacts the shaft cage. The reinforcement needs to cover as well as link in to the heap crown to shut out punch-through.

For seismic areas, detail ductility. Stay away from brittle welds at the interface and also make sure the bars have effective hooks as well as progression durations. Where the https://www.unitedstructuralsystems.com/frequently-asked-questions/ quality shaft brings significant second, consider regional shear tricks or braces focused near the pile caps to address punching and also angled tension.

If the concept consists of both helical piles and also tieback anchors along a quality beam that functions as a retaining component, distinct the tons paths. The tieback anchors need to combine to embedded plates or even walers connected to the support cage, certainly not only acquire a slim face plate.

Managing Uplift and Side Loads

One factor helical piles are actually a favored in steel-framed industrial structures is their direct uplift ability. The exact same helix layers that bear in squeezing versus soil also resist tension by bearing up. We validate through torque connection as well as tension bunch examinations. As soon as you include a level shaft, that tension requires a continual road in to the concrete. A cap plate along with bonded studs, durable hairpins, and also complete cage continuity always keeps the bunch pathway honest.

For sidewise protection, the level beam of light delivers easy resistance and also tightness while the heaps contribute by means of shaft flexing as well as ground reaction. If sidewise requirements surpass what upright heaps and also the light beam can offer, partner the body with tieback anchors. Commercial helical tieback anchor installation works properly responsible for existing walls considering that the setup is quiet and also the supports may be proof examined quickly. In soft surficial grounds, embed the 1st coil deeper to prevent overstressing near-surface soils.

Working Around Existing Issues and also Cracks

On repair ventures, grade light beams commonly tie together grounds with jagged settlement deal and a spiderweb of wall surface fractures. Foundation crack repair through epoxy shot can easily rejuvenate connection, but injection alone is going to not deal with continuous movement if soils are the offender. Combining helical piles as well as level beam of lights gives a stable bottom, after which fracture fixing makes good sense. I just like to monitor cracks with tell-tales for a couple of full weeks after tons transfer to validate stabilization just before finishing surfaces.

Where previous resistance pile or even micro pile installations exist, recognize their places. Including adjacent helical piles deeper than three sizes can easily lessen capability by means of team effects. If you need to gather supports, design the team and boost spacing or lessen bunch every heap. In some strict interior retrofits, I have alternated helical piles and micropiles to blend drivability with drillability where clutter pockets produced one unit unstable by itself.

Proof and also Functionality: Evaluating That Matters

Torque is only a stand-in. For risky or high-value projects, execute compression as well as tension bunch examinations on sacrificial or manufacturing heaps at the start of the project. A traditional compression examination course could consist of one static exam to 200 percent of layout tons and also numerous verification tests to 150 percent. For tieback anchors, proof each anchor to the pointed out lock-off bunch as well as maintain hold durations per the specification. Document creep costs and rebound. These amounts guarantee the designer of document as well as offer the crew assurance when they observe torque patterns match tested capacities.

Instrumentation may be as simple as dial evaluates during the course of hoisting or even as involved as strain gauges as well as data lumberjacks on long-span level beams. On one lab project, our team installed displacement transducers around beam periods as well as viewed the curve settle within design limits over 48 hours as loads transferred. That easy feedback always kept the owner comfortable with the procedure as well as prevented last-minute adjustment orders.

Cost, Plan, and also Threat Trade-offs

Owners respect expense and also opportunity, but the most affordable offer performs not always create the most affordable complete cost. Helical piles commonly minimize indirect costs:

- Compressed timetable due to prompt capacity and no cement treatment standing by, which can easily prune full weeks on phased retrofits.

Material prices differ along with steel markets, however labor rides amount to expense. Staffs who focus on commercial helical pile installation step rapidly, while a staff brand new to the device can easily melt times chasing after twist criteria. In infected grounds, helicals stay clear of spoils and disposal fees that come with bored heaps. If the borings disclose cobbles or rubble fill, spending plan emergencies for impediments, offsets, and a backup plan like a handful of micropiles in concern zones.

Commercial resistance pile setup may pencil better on well-maintained, gentle clay-based internet sites with generous accessibility as well as sound tolerance, particularly when capacities per heap are actually high. Micropiles make their maintain when stone sockets are important and also when you must strand a pile via aged groundworks. The most effective spending plans include allowances as well as selection gateways connected to very early field efficiency, not simply newspaper designs.

Common Downfalls and Just how to Stay away from Them

The fastest technique to waste time is to play down investigation as well as link appointing. Inadequate geotechnical records leads to surprises, as well as flimsy connections weaken ability. Misaligned caps may bind encouragement and also power field remedies that consume times. Another snare is taking over tons sharing between piles are going to be equal without verification. If one heap hits thick sand while its neighbor backsides shallow, the level beam can wind up bring unexpected moments.

Avoid these through establishing approval requirements up front. Include a reasonable torque home window, minimal embedment depths, as well as crystal clear quit policies for blockages. Require delegations with the particular helical pile style, twist connection factor, and hat particulars. Have the architectural designer evaluation assembly techniques when limits become part of the primary payload pathway. For existing constructs, pre-surveys and also vibration surveillance maintain the manager informed and lessen hands directing when hairline cracks appear.

A Case Instance From the Field

A three-story health care office complex needed an MRI collection with tight resonance restrictions. The existing slab-on-grade rested over 8 to 12 feets of undocumented filler, at that point interbedded silts as well as sands. Traditional escalate grounds would certainly work out way too much. Steered heaps were off the dining table because of vibration and closeness to occupied room. Our team used helical piles under brand-new level beams that held the MRI vault walls and tools pad.

Borings showed a dense sand level starting at about 22 feets. Our company developed for 40 kips every turn in squeezing along with a twist criterion of 8 to 9 k-ft based on the producer's assessed Kt aspect. Manufacturing piles reached 9 to 11 k-ft at 24 to 26 feets. Our company proof assessed four piles to 60 kips along with less than 0.3 inches overall motion. Grade shafts were 24 inches vast through 30 inches deep, along with minute steel tuned to cover in between stack heads at 8-foot spacing and also to circulate the massive pad load.

Because the collection was inside an active wing, our experts cut and got rid of piece strips in the evening, put in stacks and also encouragement within the day, as well as poured shafts over pair of weekends. When the beams arrived at durability, we moved lots and viewed negotiation evaluates for a full week. Activity maintained under 1/16 in. The MRI vendor accepted vibration, as well as the manager steered clear of a routine slide that would possess set you back 6 figures.

Integrating Tiebacks along with Grade Beams at Retaining Elements

Many business ventures mix grade beam of lights along with retaining wall surfaces or even cellar walls that require lateral restriction. Helical tieback anchors are actually an organic companion in rough soils or even tight clays. The procedure installs anchors with pre-formed sleeves or wallets in the wall, then pairs them to a waler or directly to improved zones in the quality light beam. For wall structures under 15 feets along with modest additional charge, a single row of tiebacks at mid-height can handle deflection. Taller walls may need 2 rows. The pattern concerns: install and evaluate tiebacks before pouring the hat or grade beam of light when possible, so you can stress in to a strong element.

If grounds are actually weak or there is actually a risk of creep, think about switching to grouted supports or even micropile-based rakers. In city web sites with property line constraints, tiebacks may crash underground. Early control with neighbors maintains you out of courthouse. Where easements are actually inconceivable, water pipes rakers bearing upon brief footings can lug loads until long-term slabs and beams lock in the structure.

Integrating with Other Deep Structure Methods

A hybrid approach is actually typically the best response. I have made use of helical piles for wall structures as well as slab upper hands, with micropiles under massive column collections where requirement went over one hundred kips and also rock outlets were actually intended. Protection stacks provided economy under gently filled canopies in soft clay-baseds, where vibration limitations were actually looser. Helical anchors maintained a small cut alongside a brand new grade ray of light while powers were transferred. Versatility is actually the market value: pick the device that operates finest in each region and connect it all in addition to quality beams that may fit various heap crown details.

Coordination illustrations need to reveal each stack type, crown altitude, cap detail, and shaft support transitions. If the property will view potential growths, leave beam ends and also heap locations that can easily accept splices or soldered layers for potential relationship, rather than jackhammering finished work later.

Quality Control That Sets up Confidence

Quality control is actually not overwrought documentation. On internet site, our experts maintain simple, regular records: pile ID, location, lead and expansion pattern, helix setup, twist by depth, ultimate torque and also depth, cap type, welds completed, and also assessor initials. For grade ray of lights, our experts tape-record rebar heat energy numbers when needed, bar spacing examinations, cover talk to a cover meter, and also concrete cyndrical tube breaks.

For deep foundation repair ventures, a baseline study of elevations at row lines and crack widths pays dividends. After bunch transmission, a second study reveals movement. If a corner rises much more than foreseed, we adjust shims and also lifts in the next phase. Integrate those reports with a clean as-built that takes note genuine heap areas, since field offsets invariably occur.

What Managers and also Developers Ought To Talk To Prior To Starting

Before committing to helical piles and also grade beams, request a few focused questions:

- Do the borings and lab tests assist the twist correlations suggested for the helical body and also coil geometry? Are uplift as well as side needs fully accounted for in the stack matter and connections, or even is a tieback anchor body required to share load? Will gain access to, clearance, or existing powers limitation devices or even pile spans, as well as do our team have pre-approved replacements like micropiles if shapes vary coming from the report? Are pile-to-beam relationships described for the regulating restriction state, along with room in the crate for installment as well as inspection? What is actually the testing plan, and exactly how are going to we incorporate outcomes right into recognition requirements without ceasing the job?

A clear yes to those concerns prepares the project on a secure course.

Final Thoughts From the Field

Helical heaps paired with level beams deal with an extensive scale of commercial groundwork problems: adjustable dirts, minimal access, uplift and lateral demands, as well as the consistent push of routine. They are actually not a silver bullet. Particles fills up, cobbles, as well as tough antarctic tills can defeat helical air travels, as well as very high tons may demand micropiles or even pierced shafts. But in many commercial foundation stabilization scenarios, specifically retrofits and internal builds, they provide a well balanced mix of velocity, management, and also verifiability.

The job does well when geotechnical as well as building teams team up, when staffs log twist like it matters, as well as when hookups are detailed with the same care as the stacks themselves. Mixture helical piles along with tieback anchors where wall structures require restriction, and do certainly not hold back to interfere protection heaps or even micropiles where situations call for all of them. Maintain the load path apparent coming from skyscraper to soil, and also create your grade beams rigid enough to share the job without hogging it. That is exactly how you turn uncertain ground right into predictable performance.